When choosing a swab for precision cleaning, the substrate and soil must first be considered because those conditions dictate if a cleaning solution is required and what kind is needed.

Smooth surfaces can be used with any swab along with a gentle solvent like IPA alcohol. Rough, abrasive, or ‘snag-prone’ surfaces require a stronger material than cotton. Chemically sensitive substrates such as rubber, silicones, and acrylics also need light solvents such as IPA, light naphtha, heptane, or isohexanes.

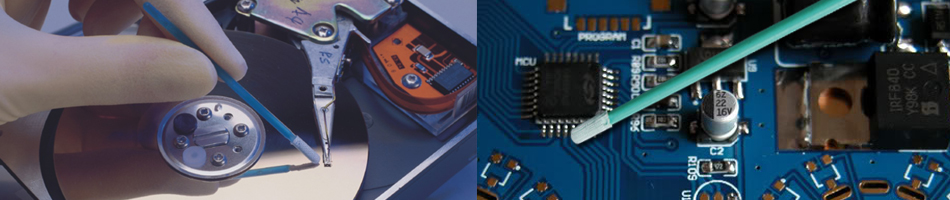

For light soils, all swab types are appropriate for use, including polyurethane foam, polyester fiber, and cotton swabs. Open-cell, polyurethane foam swabs are common for cleaning because the reticulated structure captures and holds the particles and liquids within the foam. Unlike cotton swabs, polyurethane foam swabs have no fibers that can be released and left behind. Common mild solvents like isopropyl alcohol and light hydrocarbons will work well with all of the aforementioned swabs.

Difficult to remove soils like greases, waxes, fluxes, excess adhesives, and coatings require stronger materials and may require using strong solvents and scrubbing. Cotton swabs and foam swabs will fray or tear with aggressive scrubbing, and foam tipped swabs will swell and break-down in harsh solvents. A safer choice is a more chemically resistant, tougher material like unreticulated (or closed cell) foam or knitted polyester. Unreticulated foam has an internal structure that inhibits absorption but also makes the foam much stronger and more abrasion resistant.

Knitted polyester swabs are very robust and unaffected by any solvent or solution that would be used for precision hand cleaning. Such solvents include ketones (acetone and MEK), aromatics (toluene and xylene), esters (n-butyl acetate), halogenated solvents and commercial formulations. They offer superior scrubbing ability to remove baked-on and burned-on greases, partially cured adhesives and coatings and dried on flux residues. Knitted polyester abrasion resistance makes it the best choice for scrubbing on rough surfaces, crusty contaminants, and around PCB components and leads which would shred softer materials such a foam.

Precision Cleaning Selection Review

- Identify the substrate. Determining the substrate will narrow down the type of swab that you need. Plus, it helps limit the type of solvents that are available to your application.

- Identify the soil that you are cleaning. Whether it’s easy to remove dust, particulates, and light oils, or difficult to remove soils such as greases, fluxes, adhesives, waxes, and coatings.

- Decide if a cleaning solvent is necessary. By now you will have enough information to know if and what kind of solvent is needed.

- Select swab. For gentle cleaning with nothing or a mild solvent, use any swab. Foam for low cost, quick single use, softness, and conformity to a surface. Polyester for highest cleanliness and highest strength. For aggressive cleaning with a solvent, consider a chemically tolerant swab like polyester. If cleaning an abrasive surface, consider a stronger swab like polyester. If you are working on sensitive electronics, see details on static dissipative swab handles.

- Match swab size and shape to the area, recess, or crevice being cleaned.

Source: chemtronicseu

Cleanroom Foam Swabs, Polyester Swabs, Printer Cleaning Kit Manufacturer – MediTech

Cleanroom Foam Swabs, Polyester Swabs, Printer Cleaning Kit Manufacturer – MediTech