An ESD (Wyładowania elektrostatyczne) safe swab is designed to prevent static buildup and protect electronic components from damage due to static charge transfer. These swabs are made with anti-static handles and unique tips that prevent the accumulation of lint or residue.

What are some common applications for ESD safe swabs?

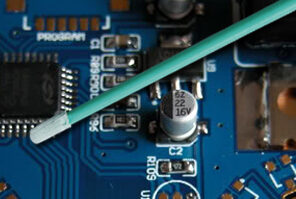

ESD safe swabs are commonly used in manufacturing and industrial applications where electrostatic discharge (ESD) is a major concern. Static can easily damage delicate electronics or medical device components, and ESD safe swabs are specifically constructed to clean small surfaces and apply precise amounts of solvents without the risk of transmitting damaging static shocks. These swabs are designed to prevent static buildup and protect electronic components from damage due to static charge transfer.

ESD safe swabs are used for applying and removing lubricants, adhesives, and other solutions in a critical clean environment with ESD concerns as well as scrubbing recessed areas. They are useful precision tools for technicians and operators to perform delicate and meticulous tasks like precision cleaning, repair, and assembly. The types of swabs can range from low-cost cotton buds on a wooden stick to highly engineered cleanroom woven materials with a specialized head shape.

ESD safe swabs are particularly useful for precision cleaning or applying precise amounts of adhesives, rozpuszczalniki, or other fluxes to minute parts in small devices, from electronic circuit boards to delicate medical devices. They are also suitable for cleaning electronics and equipment, removing residues and contaminants, and for use on optics and lenses.

ESD safe swabs are essential tools for technicians and operators who perform delicate and meticulous tasks like precision cleaning, repair, and assembly. These swabs are typically used in specialty applications and require specific size, shape, and tip features.

Wymazówki piankowe do pomieszczeń czystych, Wymazy poliestrowe, Producent zestawu do czyszczenia drukarki – MediTech

Wymazówki piankowe do pomieszczeń czystych, Wymazy poliestrowe, Producent zestawu do czyszczenia drukarki – MediTech