Cleaning validation is a crucial process in industries where cleanliness is paramount, such as pharmaceuticals, biotechnology, and medical devices. Choosing the appropriate swab for cleaning validation is essential to ensure accurate and reliable results. This article provides guidance on selecting the right swab for effective cleaning validation. By understanding the importance of swab selection, you can enhance your cleaning validation process and achieve regulatory compliance while maintaining product quality.

Factors to Consider When Selecting a Swab

1. Material Compatibility

Select a swab made from materials compatible with the cleaning agents and residues encountered in your specific cleaning validation process. Common materials include polyester, foam, microfiber, and cotton.

2. Size and Shape

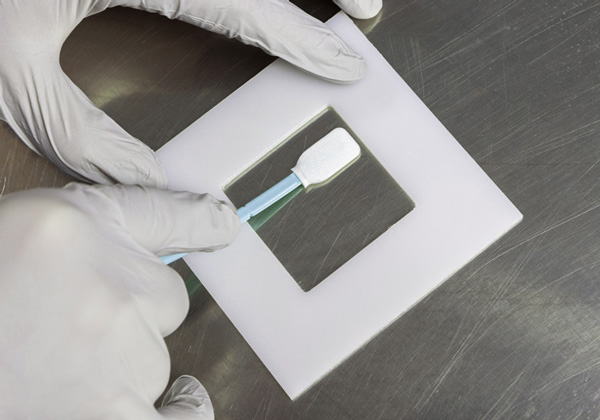

Consider the size and shape of the swab tip to ensure it can access and effectively clean the targeted areas. Different tip shapes, such as pointed, rounded, or flat, may be suitable depending on the surface or equipment being cleaned.

3. Low Particulate Generation

Opt for swabs that generate minimal particles or fibers during use. This helps prevent contamination and interference with the cleaning validation process.

4. Sterility Options

Depending on your industry requirements, sterile swabs may be necessary to minimize the risk of introducing microorganisms during cleaning validation. Ensure the swabs meet the necessary sterility standards.

Selecting the right swab is crucial for effective cleaning validation. By considering factors such as material compatibility, size, shape, and sterility options, you can ensure accurate and reliable results in your cleaning validation process. MediTech is a manufacturer that has focused on the production of cleanroom swabs for more than 10 years. If you are interested in our cleanroom swabs, please contact us, we will not only provide you with trustworthy cleanroom swabs, but also give you professional guidance and suggestions.

Cleanroom Foam Swabs, Polyester Swabs, Printer Cleaning Kit Manufacturer – MediTech

Cleanroom Foam Swabs, Polyester Swabs, Printer Cleaning Kit Manufacturer – MediTech