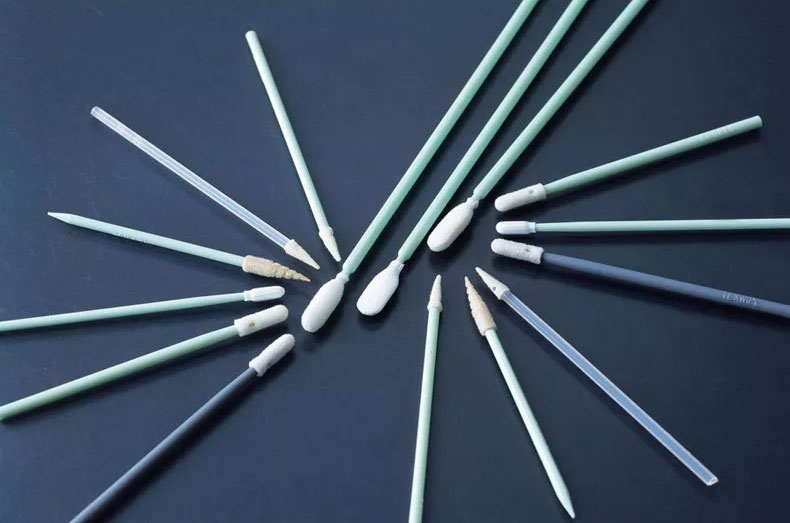

เราทุกคนรู้ดีว่าสำลีก้านธรรมดา, คือผ้าฝ้ายพันตรงที่จับด้านบน, แล้วไม้กวาดคลีนรูมถูกผูกมัดอย่างไร? ส่วนใหญ่มี 3 ได้ดังนี้.

- Directly glue the head of the cleanroom swab to the handle

Some manufacturers use glue or other sticky substances to stick the head on, as long as it doesn’t fall off. Although such a production process is very simple to produce, it cannot be used for industrial use, because they have some residues on them, which can easily cause the residues to fall on the product, causing secondary pollution and poor cleaning effect.

- The principle of heat sealing

First, hot-press the head of the cleanroom swab with hot air, and our cleanroom swab uses such a production process. Because hot air can blow off some of the original dust on the cotton swab, and the cotton swab head and the cotton swab shaft are more closely joined together, leaving no residue, and the cleaning effect is good. Can be used longer!

- Production using ultrasound

The principle is to use high-frequency vibration waves to transmit to the surfaces of two objects to be welded, and under pressure, the surfaces of the two objects are rubbed against each other to form fusion between the molecular layers. Although the quality of cotton swabs produced by ultrasonic is the best, its cost is not low.

Through the above three points, have you learned more about the cleanroom swab? เมดิเทค is not only to sell products to customers, but also to go all out to curb the occurrence of defective products at the source and ensure that customers can use them with confidence.

คลีนรูมโฟม Swabs, โพลีเอสเตอร์ Swabs, ผู้ผลิตชุดทำความสะอาดเครื่องพิมพ์ – เมดิเทค

คลีนรูมโฟม Swabs, โพลีเอสเตอร์ Swabs, ผู้ผลิตชุดทำความสะอาดเครื่องพิมพ์ – เมดิเทค